CORE_COMPETENCE

Product_Leaders

index_more

index_more_content

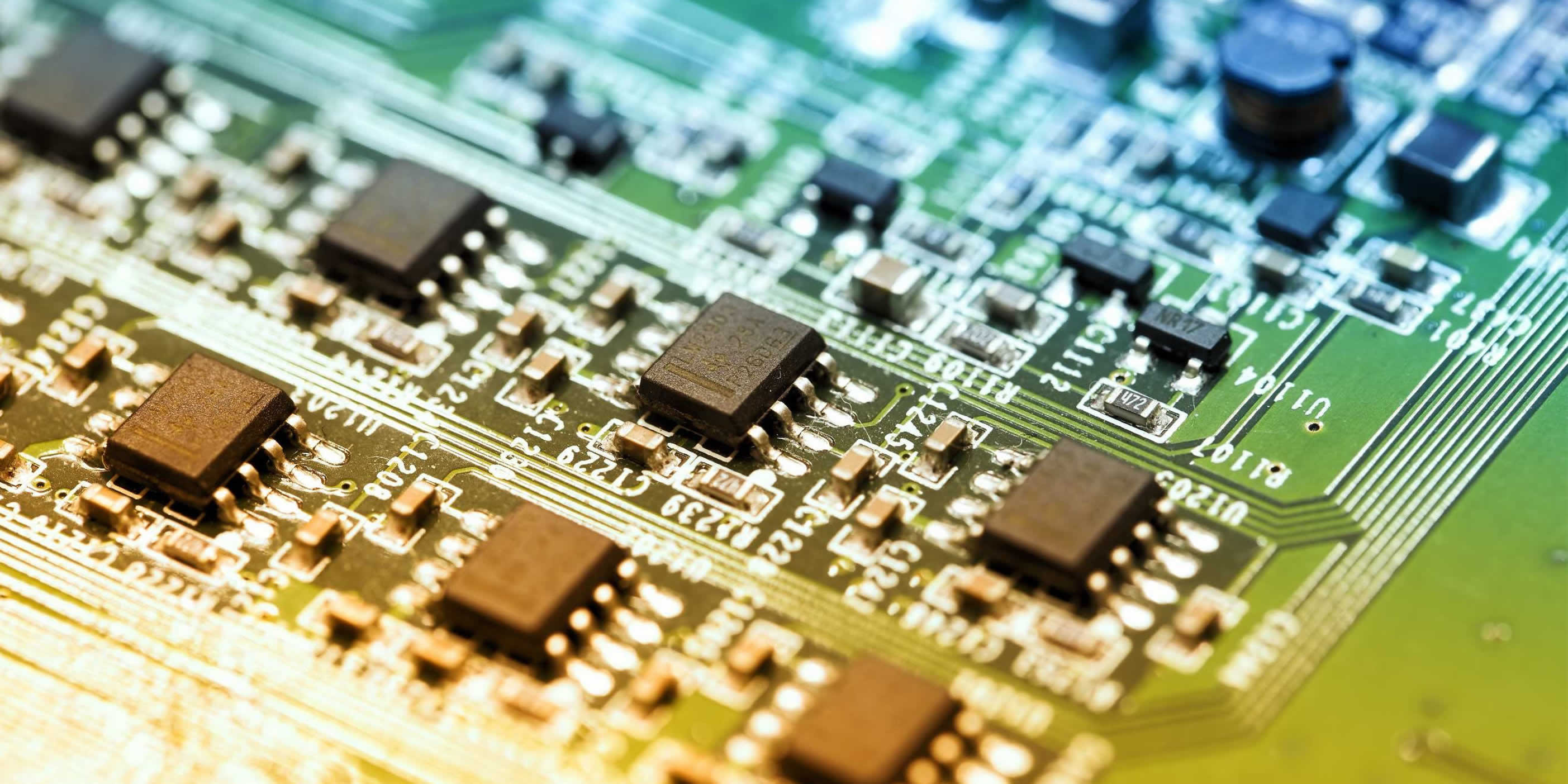

info_item01

info_item_content01

info_item02

info_item_content02

info_item03

info_item_content03

info_item04

info_item_content04

NEWS

NEWS

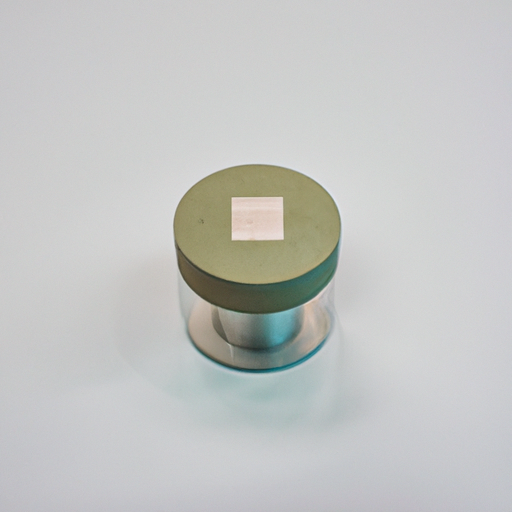

application development in Pressure Sensors, Transducers for CFR-25JB-52-11R: key technologies and success stories

Application Development in Pressure Sensors and Transducers for CFR-25JB-52-11R: Key Technologies and Success StoriesThe development of pressure sensors and transducers, such as the CFR-25JB-52-11R, is a dynamic field that leverages cutting-edge technologies to meet the demands of various industries. Below is a detailed overview of the key technologies involved and notable success stories that illustrate the impact of these sensors.

Key Technologies1. MEMS Technology2. Digital Signal Processing (DSP)3. Wireless Communication4. Smart Sensors5. Temperature Compensation6. Robust Materials7. Calibration and Testing1. Aerospace Industry2. Automotive Sector3. Oil and Gas4. Medical Devices5. Industrial Automation6. HVAC Systems Success Stories ConclusionThe development and application of pressure sensors and transducers, such as the CFR-25JB-52-11R, are driven by technological advancements and the increasing demand for precision and reliability across various industries. The success stories in aerospace, automotive, oil and gas, medical devices, industrial automation, and HVAC systems underscore the critical role these sensors play in enhancing safety, efficiency, and performance. As technology continues to evolve, the potential for innovative applications and improvements in pressure sensing technology will only expand, paving the way for new opportunities and advancements in various fields.

2025-07-05

2